Views: 0 Author: Site Editor Publish Time: 2026-02-24 Origin: Site

Are you looking for a more efficient way to cool industrial processes? Have you ever considered the benefits of a spiral cooling tower?

In this article, we'll explain what a spiral cooling tower is and how it works. You'll discover its advantages over traditional cooling systems, including better space efficiency and energy savings.

Component | Description |

Spiral Casing | Forms the helical shape for airflow and water circulation. |

Fan | Circulates air through the tower for efficient cooling. |

Water Distribution System | Ensures even water distribution for optimal heat dissipation. |

Drift Eliminators | Reduces water droplets in the exhaust air to minimize loss. |

Water Inlet | Entry point for the water to be cooled. |

Outlet | Exits cooled water back into the system or process. |

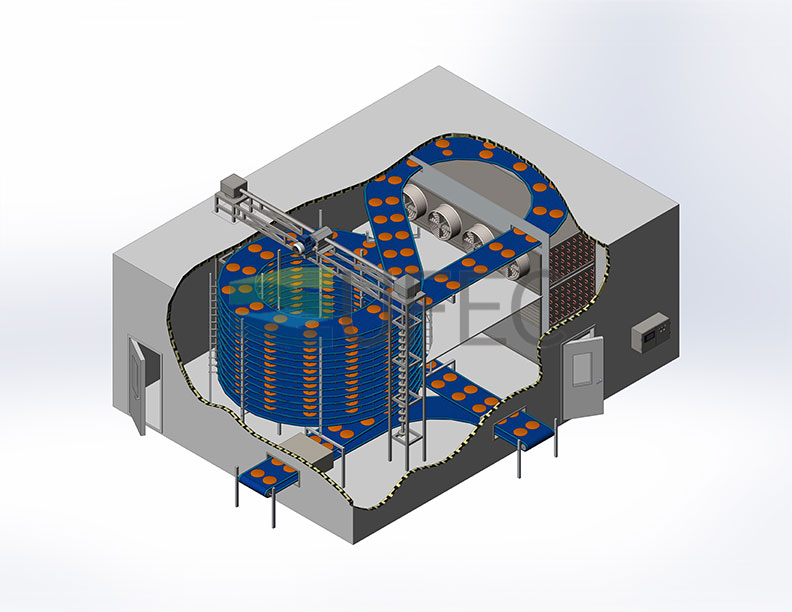

A spiral cooling tower is an innovative type of heat dissipation system widely used to cool water in various industrial processes. The design features a spiral or helical structure, which is significantly different from traditional vertical or hyperboloid towers. This helical shape enables more efficient airflow and water distribution, allowing the system to operate at higher efficiency levels. The spiral design maximizes the surface area for water evaporation, thereby enhancing heat transfer between the water and the surrounding air. This efficient heat exchange process helps to achieve faster and more effective cooling.

The structure consists of several key components:

● Spiral casing: The main body of the tower, which forms the helical shape. The spiral casing is designed to optimize airflow and water distribution as they interact in the cooling process. It plays a critical role in enhancing the system’s cooling efficiency.

● Fan: Positioned at the top or bottom of the tower, the fan circulates air through the system. By ensuring constant airflow, the fan helps to accelerate the evaporation process and improve the heat transfer efficiency between the water and the air.

● Water distribution system: This system is designed to evenly spread water across the spiral casing, ensuring uniform coverage and efficient cooling. The even distribution of water increases the surface area exposed to the air, enhancing the evaporation process.

● Drift eliminators: These are designed to capture and remove water droplets from the exiting air. By reducing the amount of water lost in the air, drift eliminators help in maximizing water conservation and minimizing environmental impact.

This configuration results in more effective heat exchange and lower energy consumption than conventional cooling towers.

The spiral cooling tower is designed with efficiency in mind. The helical structure ensures that air flows more efficiently, helping to cool the water faster. Unlike traditional designs, this shape optimizes space and reduces the footprint required for installation.

The water flows down the spiral ramp, while air flows upward, facilitating continuous heat transfer. This combined flow system maximizes cooling efficiency and reduces energy usage.

In a spiral cooling tower, water is pumped to the top of the spiral structure and then flows down in a helical path. As the water travels down the spiral ramp, it is exposed to air that flows upwards through the tower. The water and air exchange heat, with the water losing heat and the air gaining it.

This heat exchange process is accelerated by the unique spiral design, which increases surface contact between the water and the air, facilitating better evaporation. The cooler water then exits the tower and is ready for reuse in the industrial process.

The spiral cooling tower’s design ensures that the air flows in a vertical pattern, which reduces the need for large fans. The fan at the top or bottom circulates the air, pushing it upward through the spiral tower. As air rises, it draws heat from the water cascading down the spiral ramp.

The combination of gravity-driven water flow and forced air flow leads to an efficient cooling cycle. The helical shape reduces the resistance to airflow, which further minimizes energy consumption in the cooling process.

One of the main benefits of spiral cooling towers is their compact design. Traditional cooling towers can occupy large areas, but the spiral configuration allows for a smaller footprint while still offering high cooling capacity. This is particularly valuable in industries where space is limited or costly.

Spiral cooling towers are ideal for urban and industrial environments where space constraints are common. Their unique shape enables a higher cooling capacity per square foot compared to traditional designs.

The spiral design leads to enhanced airflow and greater surface area for water evaporation. This increased surface area helps dissipate heat more quickly, reducing the time and energy required for cooling. As a result, spiral cooling towers offer a more efficient cooling process, which translates to lower operational costs.

Spiral cooling towers are built to last. Their robust design requires less frequent maintenance and has a longer lifespan compared to conventional cooling towers. The materials used are corrosion-resistant, ensuring that the system remains functional even in harsh industrial environments.

Furthermore, the efficient design minimizes water loss and reduces the accumulation of debris, making the system easier to maintain over time.

Feature | Spiral Cooling Tower | Traditional Cooling Tower |

Design | Helical, compact | Large, vertical or hyperboloid |

Cooling Efficiency | Higher due to better airflow | Lower efficiency in some cases |

Space Efficiency | More compact design | Requires more space |

Energy Consumption | Lower energy use | Higher energy consumption |

Maintenance Requirements | Low maintenance | Higher maintenance |

Water Usage | Reduced evaporation loss | Higher water usage |

When compared to traditional cooling towers, spiral cooling towers stand out in terms of efficiency. The helical design ensures better heat dissipation, which translates into faster and more efficient cooling. This is especially true in environments where cooling demands are high.

Traditional cooling towers typically have large surface areas and high operational costs. In contrast, spiral towers use less energy and space, making them a more sustainable choice for industries aiming to reduce their environmental footprint.

Though spiral cooling towers might require a higher initial investment, their long-term operational savings outweigh the upfront costs. The reduction in energy consumption and water usage leads to lower operating costs, providing significant savings over time.

For businesses that require consistent cooling, investing in a spiral cooling tower is a cost-effective decision in the long run.

Spiral cooling towers are used across various industries, including power plants, manufacturing facilities, and refineries. These industries require large-scale cooling systems to manage the heat produced during operations, and spiral cooling towers offer a space-efficient and energy-saving solution.

For example, in power plants, the cooling system is critical to maintaining safe operational temperatures. The efficient heat dissipation provided by spiral cooling towers ensures optimal performance without wasting valuable resources.

Beyond their operational efficiency, spiral cooling towers contribute to environmental sustainability. Their design minimizes water usage by reducing evaporation losses. The reduced need for water and energy translates into a lower environmental impact, making these towers an excellent choice for businesses seeking to meet sustainability goals.

As technology continues to advance, spiral cooling towers are evolving. Innovations in materials, such as corrosion-resistant alloys and energy-efficient fan designs, are making these towers even more effective. Furthermore, the integration of smart sensors for real-time monitoring and optimization is becoming a key trend in improving tower performance.

With these developments, spiral cooling towers are poised to become even more efficient and adaptable to the growing needs of industries worldwide.

As industries across the globe focus on energy efficiency and environmental responsibility, the adoption of spiral cooling towers is expected to increase. Their ability to provide high-efficiency cooling with minimal space and energy use positions them as a leading solution in both developed and emerging markets.

A spiral cooling tower is an efficient solution for industrial cooling. Its unique design improves space efficiency and enhances heat dissipation. Compared to traditional towers, it reduces energy consumption and operational costs. Companies like HANGZHOU REACH BUILDING CO., LTD.provide these cutting-edge systems, offering robust and cost-effective cooling solutions for various industries.

A: A spiral cooling tower is a heat dissipation system with a helical design, improving airflow and water evaporation efficiency for industrial cooling.

A: The spiral cooling tower circulates water through a helical ramp while air flows upward, facilitating effective heat transfer and cooling.

A: A spiral cooling tower saves space, reduces energy consumption, and provides better cooling efficiency compared to traditional towers.

A: Spiral cooling towers offer space efficiency, lower operational costs, and better environmental sustainability due to reduced water and energy usage.

A: Spiral cooling towers are commonly used in power plants, manufacturing facilities, and refineries for efficient industrial cooling.