Views: 0 Author: Site Editor Publish Time: 2026-02-07 Origin: Site

Cooling is essential for maintaining the freshness of baked goods, but how can bakeries optimize this process? One solution that stands out is the spiral cooling tower. These innovative systems promise efficiency and speed, but do they live up to the hype? In this article, we will explore the efficiency of spiral cooling towers in the context of baked goods.

You will learn how they work, their benefits, and the factors to consider when integrating them into your bakery. Let’s dive into the details and find out how spiral cooling towers can enhance your production process.

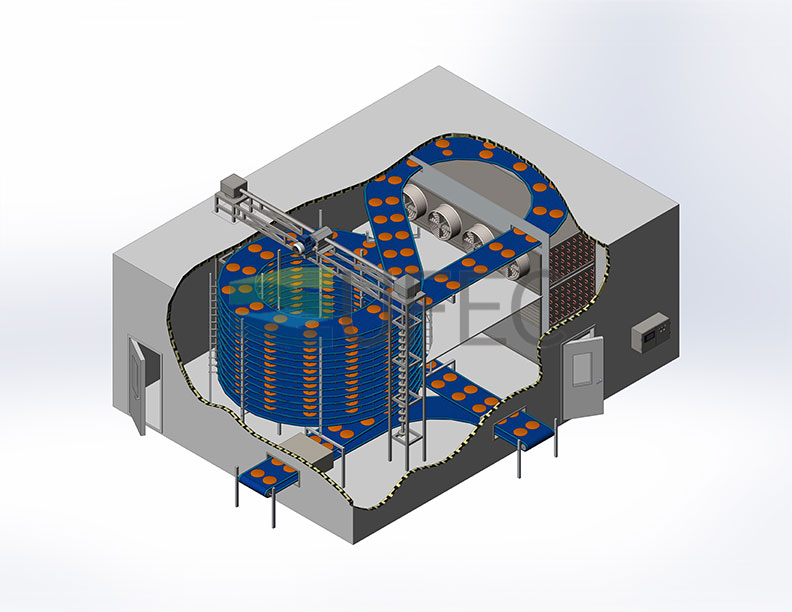

A spiral cooling tower is a specialized industrial cooling system designed to handle products like baked goods in continuous production processes. These towers are built with a spiral conveyor system, allowing baked goods to travel along a controlled cooling path. The cooling air is evenly distributed, maintaining a consistent temperature throughout the tower. This process ensures that each product is cooled efficiently without the need for manual intervention.

Spiral cooling towers differ from traditional cooling methods in that they provide more space-efficient cooling. The spiral design saves floor space while offering a more consistent cooling rate, which is critical for delicate baked goods.

Spiral cooling towers are particularly suited for baked goods because of their unique design that ensures even airflow. The design minimizes the chances of hot spots, which can lead to uneven cooling and potential spoilage. The cooling air flows around the goods in a spiral pattern, ensuring that they are exposed to air from all angles, speeding up the cooling process.

These towers are also designed to handle different product sizes, from small pastries to large loaves of bread, making them a versatile option for bakeries of all sizes.

One of the key advantages of spiral cooling towers is the increase in production efficiency. With traditional cooling methods, cooling can take up to several hours, during which time products cannot be moved or processed. Spiral cooling towers accelerate the cooling process by using controlled airflow and minimal handling, enabling products to be cooled quickly and efficiently.

This speed not only increases production throughput but also reduces the time required for each batch of baked goods to be ready for packaging, thus improving the overall production cycle.

Cooling baked goods too slowly or unevenly can compromise their texture, freshness, and overall quality. Spiral cooling towers help maintain the desired texture by cooling products in a uniform manner. Since cooling is done evenly, it reduces the chances of moisture buildup, which can make baked goods soggy.

Additionally, maintaining optimal cooling temperatures prevents condensation and mold growth, which can spoil products. As a result, spiral cooling towers play a vital role in ensuring that baked goods maintain their quality from oven to packaging.

Energy consumption is a concern in any industrial process, and cooling is no exception. Spiral cooling towers are designed to be more energy-efficient than traditional methods like batch cooling. The compact design and efficient airflow reduce the need for excessive cooling power, which translates to lower energy costs over time.

Compared to other cooling systems, spiral towers use a smaller footprint and require less maintenance, resulting in long-term energy savings.

Regular maintenance of the cooling fans and air distribution system can help further enhance energy efficiency.

Feature | Spiral Cooling Tower | Traditional Cooling Methods |

Cooling Time | Faster cooling, reduces time | Slower cooling, takes longer |

Energy Consumption | Lower energy consumption | Higher energy consumption |

Space Efficiency | Compact design, saves space | Requires larger space for setup |

Labor Costs | Reduced due to automation | High labor costs for monitoring |

Product Quality Maintenance | Consistent and even cooling | Possible uneven cooling leading to spoilage |

Spiral cooling towers reduce the need for manual labor in the cooling process. With traditional methods, workers are often required to monitor and handle products as they cool, moving trays or carts of baked goods to different cooling areas. In contrast, spiral cooling towers automate the cooling process, allowing baked goods to be transported automatically along the cooling conveyor.

This automation cuts down on labor costs by reducing the number of staff required to monitor the cooling process. Additionally, fewer mistakes or accidents occur, as products are handled less frequently.

One of the biggest advantages of spiral cooling towers is their space-saving design. In many bakeries, space is limited, and floor space must be maximized for other essential operations. Traditional cooling methods require large, flat spaces for cooling racks or batch cooling systems, which can take up a significant amount of room.

The spiral design of these cooling towers allows products to be stacked in a vertical spiral, making efficient use of floor space while providing ample airflow to each product. This space-saving feature allows bakeries to increase their overall production capacity without needing additional floor space.

Spiral cooling towers are ideal for bakeries with high production volumes where space is at a premium. They work best in bakeries that produce a variety of baked goods, from pastries to bread, and where consistent cooling is essential to maintaining product quality.

They are also beneficial in facilities that operate on a continuous production schedule, where minimizing downtime between batches is crucial. If a bakery runs multiple lines or requires cooling for delicate or temperature-sensitive goods, spiral cooling towers can significantly improve efficiency.

While spiral cooling towers are efficient, they may not be the right choice for every bakery. For smaller operations or bakeries with lower production volumes, the initial investment in a spiral cooling tower may not be cost-effective. Additionally, the complexity of installation and maintenance might be a challenge for some bakeries.

Another limitation is that spiral cooling towers are designed for specific temperature and humidity control. They might not be ideal for products that require highly specialized cooling conditions, such as frozen goods or certain types of confections.

Consider the size and scale of your production before investing in a spiral cooling tower. It’s best suited for medium to large operations with steady production volumes.

Several bakeries have successfully integrated spiral cooling towers into their production lines. For example, a large-scale bakery in Europe implemented spiral cooling towers to replace their traditional cooling racks. This change resulted in a 30% increase in production capacity while reducing cooling time by 40%. The bakery was able to maintain the same level of product quality with fewer labor costs.

After the implementation of spiral cooling towers, many bakeries reported significant improvements in both efficiency and product quality. One bakery noted that their cooling process, which previously took up to three hours per batch, was reduced to less than an hour, allowing them to triple their production output.

Look for manufacturers with proven success in your specific bakery type to get the most out of spiral cooling towers.

When selecting a spiral cooling tower, it’s important to consider the size of your production line and the types of baked goods you produce. Ensure that the tower can handle the volume and variety of your goods. Additionally, assess the cooling capacity to ensure it meets your bakery’s needs.

It’s also important to look at the reliability of the cooling tower’s components, such as the conveyor system and fans, to avoid unexpected maintenance costs.

Factor | Consideration | Importance |

Bakery Production Volume | Larger volumes require higher capacity | High |

Product Variety | Need for flexibility in cooling goods | Medium |

Cooling Capacity | Ensures efficient and fast cooling | High |

Floor Space Available | Compact design for space-saving | High |

Maintenance Requirements | Frequency and cost of maintenance | Medium |

Experts recommend consulting with a cooling tower manufacturer who understands the nuances of bakery production. They should offer customized solutions based on your bakery’s needs and help you select the right model for your specific requirements.

Always request a demo or case study from the manufacturer to understand how the cooling tower will fit into your existing operation.

Spiral cooling towers offer a highly efficient solution for cooling baked goods, improving production speed and product quality. They help bakeries save space and reduce labor costs while maintaining consistent cooling. HANGZHOU REACH BUILDING CO., LTD. provides advanced spiral cooling towers that ensure optimal temperature control, enhancing both efficiency and product freshness in bakeries.

A: A spiral cooling tower is an industrial cooling system designed to cool baked goods efficiently. It uses a spiral conveyor to ensure even airflow and fast cooling.

A: By automating the cooling process, a spiral cooling tower speeds up cooling times, reducing labor and increasing overall production throughput.

A: A spiral cooling tower offers energy efficiency, consistent cooling, and space-saving design, making it ideal for bakeries with high production volumes.

A: While efficient, spiral cooling towers may not be cost-effective for small-scale bakeries or those with highly specialized cooling needs.