Views: 0 Author: Site Editor Publish Time: 2026-01-09 Origin: Site

Cooling towers are a common solution for industrial cooling, but do they really work as promised? Are they as efficient as advertised, especially when it comes to Spiral cooling towers?

In this article, we’ll explore the functionality of cooling towers, focusing on Spiral cooling towers, and answer the key question: Do they truly live up to expectations? You’ll learn how they work, their advantages, and whether they are the right fit for your business needs.

At its core, a cooling tower is a device designed to remove heat from industrial systems, using evaporation to dissipate excess heat into the atmosphere. Cooling towers function by taking in warm water and passing it over fill media. As the water moves, a portion of it evaporates, carrying the heat away and cooling the remaining water. This process is essential for industries that rely on large amounts of water for cooling, such as power plants, chemical factories, and even bakeries.

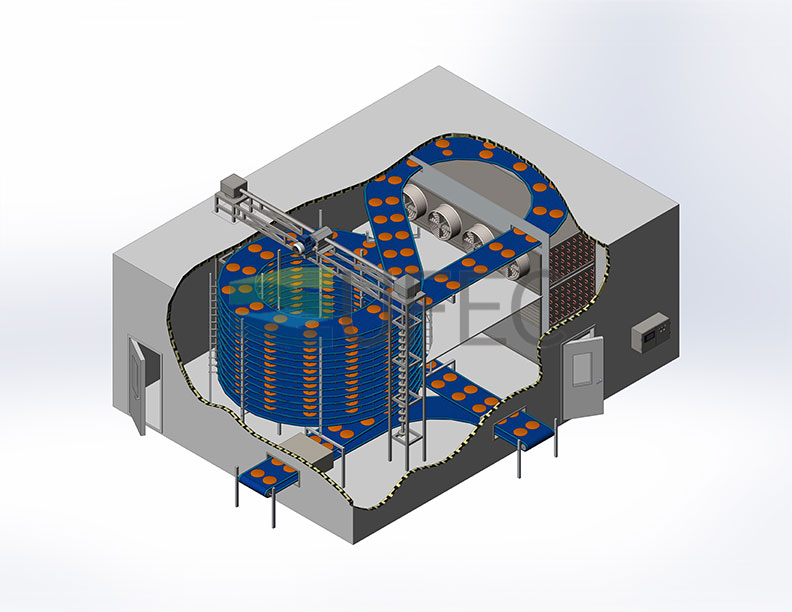

In the case of Spiral cooling towers, the water circulates through a continuous, spiral system where air is drawn in to accelerate the cooling process, enhancing the evaporation process and improving overall efficiency.

There are several types of cooling towers, including Spiral cooling towers, crossflow, counterflow, and hybrid designs. Each of these types serves a unique purpose depending on the needs of the industry.

Spiral cooling towers are often preferred for smaller, high-throughput operations because their compact design maximizes space efficiency while maintaining consistent cooling.Crossflow cooling towers: Water flows horizontally through the fill, while air enters vertically.Counterflow cooling towers: Air flows upwards while the water falls vertically.Each type has its advantages and is chosen based on space constraints, cooling capacity, and efficiency needs.

Cooling Tower Type | Design | Ideal Application | Key Benefits |

spiral cooling tower | Continuous spiral design | Small to medium-sized facilities | Compact, energy-efficient, saves space |

Crossflow Cooling Tower | Water flows horizontally | Large-scale operations, open spaces | Efficient in large systems, easy maintenance |

Counterflow Cooling Tower | Water flows vertically | High cooling capacity requirements | Effective for high heat loads, space efficiency |

Hybrid Cooling Tower | Combination of crossflow and counterflow | Versatile for various applications | Offers flexibility and can handle high capacity |

Cooling towers remove heat by transferring it from water to the surrounding air. Warm water from industrial systems enters the cooling tower and is distributed over fill media. As water flows through the media, the air passing through the tower absorbs heat from the water, causing a portion of the water to evaporate. This evaporation process helps cool the remaining water.

Spiral cooling towers enhance this process by utilizing a spiral path that continually exposes the water to air. This design maximizes the air-water contact area, improving the evaporation rate and making the cooling process more efficient.

The efficiency of a cooling tower is heavily influenced by the even distribution of water and airflow. A well-designed spiral cooling tower ensures that air flows consistently around each water droplet, preventing hot spots that could lead to inefficiency. Fans, water distribution systems, and fill media all play a critical role in maintaining uniform conditions.

In Spiral cooling towers, the spiral design allows for continuous movement of both water and air, creating an even and efficient heat dissipation process.

What makes Spiral cooling towers unique is their compact, continuous design. Unlike traditional cooling towers, which require large, flat areas, Spiral cooling towers save space by allowing products to be cooled vertically in a spiral path. The spiral layout increases the time that the water is exposed to air, enhancing the cooling process.

This design is particularly useful for smaller to medium-sized industrial operations, such as bakeries or small factories, where space is limited but cooling needs remain high.

One of the primary benefits of cooling towers is their ability to improve operational efficiency. In industrial systems where high heat loads are common, cooling towers ensure that the temperature is kept at optimal levels. By continuously circulating water through a spiral cooling tower, industries can keep machinery and systems running smoothly without overheating.

This leads to fewer breakdowns, increased uptime, and better overall efficiency in production.

Benefit | Description | Why It Matters |

Energy Efficiency | Reduced energy consumption compared to traditional cooling methods | Saves on electricity, reducing operational costs |

Space-Saving Design | Vertical spiral system reduces the need for floor space | Maximizes space for other operations or equipment |

Reduced Cooling Time | Faster cooling process due to optimized airflow | Increases production throughput and minimizes downtime |

Improved Product Quality | Even cooling prevents spoilage and maintains product texture | Helps ensure the quality and freshness of products |

Cooling towers help save on operational costs in several ways. First, they use water evaporation, which is a more energy-efficient cooling process compared to mechanical refrigeration. Spiral cooling towers are particularly energy-efficient due to their smaller footprint and higher heat dissipation capacity, leading to lower energy bills.

Second, by reducing the chances of overheating, they help extend the lifespan of machinery and equipment, saving on repair or replacement costs. Over time, these savings can add up significantly, making cooling towers a worthwhile investment.

Cooling towers contribute to reducing the environmental impact of industrial processes. By efficiently dissipating excess heat, they help prevent thermal pollution in local water bodies. The evaporative cooling process also uses less energy compared to traditional methods, further decreasing a facility’s carbon footprint.

Tip: Regularly cleaning and maintaining your spiral cooling tower can enhance its cooling efficiency and reduce environmental impact.

Cooling towers have been proven to work in a wide variety of industries. For example, a large bakery in Europe integrated a spiral cooling tower into its production line, reducing cooling time by 40% and increasing output by 30%. This allowed the bakery to maintain the quality of its products while significantly improving its operational efficiency.

When it comes to cooling towers, particularly Spiral cooling towers, the claims of energy efficiency and increased productivity hold true in many real-world applications. However, it’s important to choose the right cooling tower based on your facility’s size and cooling requirements. For smaller operations, Spiral cooling towers provide a compact, energy-efficient solution.

When choosing a cooling tower, consider factors like the size of your operation, the cooling capacity required, and the available space. Spiral cooling towers are ideal for smaller to medium-sized businesses where space is limited, but efficient cooling is still essential.

Also, consider the energy efficiency of the cooling tower and its maintenance requirements to ensure long-term savings.

Experts suggest consulting with a cooling tower manufacturer to choose a system that aligns with your cooling needs and operational goals. Spiral cooling towers are perfect for certain industries, but a customized solution will ensure that your tower operates at peak efficiency.

Cooling towers, especially Spiral cooling towers, are effective in improving cooling efficiency in various industries. They help reduce energy costs, improve operational performance, and minimize space usage. HANGZHOU REACH BUILDING CO., LTD. offers high-quality Spiral cooling towers that provide optimal cooling solutions for businesses, enhancing productivity while reducing maintenance costs.

A: A spiral cooling tower is a type of cooling system designed to efficiently cool water through a continuous spiral path, improving space utilization and cooling performance.

A: The design of a spiral cooling tower ensures more consistent airflow and water exposure, which speeds up the cooling process and reduces energy consumption.

A: Spiral cooling towers are compact, energy-efficient, and ideal for smaller operations where space is limited but cooling needs remain high.

A: While Spiral cooling towers are efficient, they may not be suitable for facilities requiring extremely high cooling capacities or specialized cooling conditions.